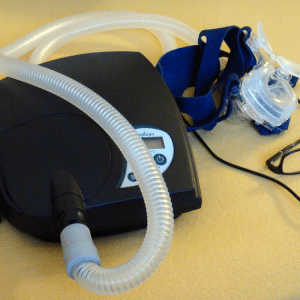

An FDA document filed on November 9 indicates that Phillips was aware of degradation issues in the polyurethane foam used in its CPAP, BiPAP and ventilator devices as early as October 2015.

Phillips recalled over 20 CPAP, BiPAP and ventilator devices in June 2021 because the polyurethane foam in them could break down, enter the devices’ air pathways and/or off-gas dangerous chemicals.

The FDA Form 483 document, filed by FDA investigator Katelyn A Staub-Zamperini, claims that Phillips was repeatedly made aware of the foam degradation issues between October 2015 and the June 2021 recall. The document also claims that Phillips did not cite any investigation or analysis when choosing which CPAP, BiPAP and ventilator devices containing the foam to recall and which devices not to recall, hinting that dangerous devices may still be on the market.

The document made eight observations:

1. Risk Analysis Is Inadequate

Staub-Zamperini found that Phillips didn’t properly perform risk analysis on their CPAP, BiPAP and ventilator devices.

“There is no documented investigation, risk analysis, or design failure mode effect analysis to support your firm’s rationale for which polyester polyurethane foam-containing products were affected, included, or not included in your firm’s ongoing recalls… you have not sufficiently demonstrated that other devices, also containing polyester polyurethane foam, should not be included in your ongoing recalls,” Staub-Zamperini wrote.

This means that Phillips may not have referred to any investigation or analysis when choosing which devices to recall and which devices not to recall, meaning that dangerous devices may still be being sold on the market as a result.

The Form 483 document states that Philips was aware of a service procedure performed on their ventilator products, related to possible foam degradation, on or around November 25, 2015, yet “no investigation, health hazard evaluation, risk analysis, or design review was performed or documented” after becoming aware of the procedure.

Staub-Zamperini also found that risk analysis was inadequate or simply not performed quickly enough following at least 14 instances of Phillips being made aware of foam degradation or volatile organic compound emission issues from April 1, 2016 to January 22, 2021. She found that an August 30, 2016 test report found that “polyester urethanes show bad resistance against high humidity in combination with high temperature.”

Phillips being made aware of the foam degrading in high humidity, high temperature conditions is a theme repeated many times throughout the document, which mentions that this phenomenon “concurred with Trilogy ventilator related complaints received from… Florida.”

The Form 483 document states that a Phillips Dreamstation 1 device failed formaldehyde emissions testing in January 2019. Formaldehyde is considered a known human carcinogen by the National Toxicology Program.

This means that Phillips was aware its CPAP, BiPAP and ventilator devices posed a potential cancer risk in 2019, yet didn’t recall the devices until June 2021.

A December 10, 2020 biological risk assessment, according to Staub-Zamperini, stated, “Potential cytotoxicity and genotoxicity leading to carcinogenicity are possible outcomes from degraded PE-PUR foam exposure,” adding that “the degraded PE-PUR foam is not considered biocompatible and presents a significant biological risk to those patient populations who are exposed to” it.

The Form 483 document states that consumer complaints, regarding Phillips’ products from January 1, 2008 to the present, the keywords “contaminants, particles, foam, debris, airway, particulate, airpath, and black” numbered over 222,000 complaints.

Staub-Zamperini noted that Phillips in 2018, stated in an evaluation that it is “possible but improbable” that their Trilogy ventilator devices would cause harm. She noted that this very same evaluation found that 14 post-market surveillance reports with associated medical device reports were filed regarding foam degradation issues, meaning that “potential foam degradation in Trilogy ventilator devices is not an isolated incident, and you also have not documented a detailed rationale for why harm is not likely to occur again.”

In other words, Phillips claimed that it was improbable their devices would cause harm, yet, in the same document, presented evidence showing that it appeared likely their devices would cause harm.

2. Procedures For Corrective And Preventative Action Have Not Been Adequately Established

Staub-Zamperini found that a corrective and preventive action (CAPA) was opened on April 12, 2018 after Phillips received complaints regarding foam degradation in Trilogy ventilator devices, but was never made into a formal CAPA. She states that opened CAPAs were only made into formal CAPAs if approved by a CAPA review board or delegates. She found that Phillips replaced foam in the devices in question, but “no verification of effectiveness was performed for this corrective and preventative action.”

The Form 483 document states that the CAPA which was opened included only Trilogy 100 and 200 ventilators, and did not include other Phillips CPAP and BiPAP devices which also contained the same foam, despite Phillips having received around 80 complaints related to foam degradation in non-Trilogy ventilator devices from 2014 to 2017.

Phillips, according to Staub-Zamperini, sent their foam supplier an email on October 30, 2015, implying that a customer made them aware of foam degradation issues. Their foam supplier replied on August 5, 2016, according to Staub-Zamperini, stating that foam degradation was “likely.”

3. Design Validation Did Not Ensure The Device Conforms To Defined User Needs And Intended Uses

Staub-Zamperini noted that a 2018 evaluation implied that Trilogy 100 and 200 ventilator devices were safe because of typical and healthy lung and bodily functions which would minimize the effects of inhaling the foam.

The evaluation claimed the following:

- Large particulate would be removed from the airway by the cilia and mucosal lining, then expectorated by the patient.

- Medium particulate would be removed from the airway by the cilia and mucosal lining through sedimentation.

- Small particulate would be subjected to alveolar macrophages which would bind to it, ingest it and digest it.

The Form 483 document refers to these bodily functions as “typical and healthy lung and bodily functions,” noting that the intended patient population of these devices includes patients with a tracheostomy and patients lacking typical and healthy lung and bodily functions.

Staub-Zamperini also noted that the evaluation based the risk of the devices on the use of a humidifier and/or bacterial filter with the Trilogy devices, noting that these parts were not needed for proper use of the devices.

4. Procedures For Design Change Have Not Been Adequately Established

Staub-Zamperini found that Philips did a serving procedure on Trilogy ventilator devices, in response to field complaints regarding foam degradation, without verifying, reviewing or validating the procedure.

5. A Correction Or Removal, Conducted To Reduce A Risk To Health Posed By A Device, Was Not Reported In Writing To FDA

Phillips, according to Staub-Zamperini, implemented a field correction of Trilogy 100 and 200 ventilator devices, connected to foam degradation, without reporting the the field correction to the FDA.

6. Management With Executive Responsibility Has Not Ensured That The Quality Policy Is Understood, Implemented And Maintained At All Levels Of The Organization

Staub-Zamperini noted that firm management, including management with executive responsibility, was aware of the foam degradation issues in CPAPs, BiPAPs and Trilogy ventilators since at least January 2020, or earlier, but failed to implement further corrective actions until April 2021.

7. Procedures To Ensure That All Purchased Or Otherwise Received Product And Services Conform To Specified Requirements Have Not Been Adequately Established

Phillips, according to Staub-Zamperini, lacked established data, documentation or written agreement which clearly referenced or described quality requirements for their raw foam supplier, or specified requirements of the raw foam they supply.

8. Potential Consultants Were Not Evaluated And Selected Based On Their Ability To Meet Specified Requirements

Staub-Zamperini found that Philips failed to evaluate, select and approve consultants as approved suppliers before hiring them as consultants on the quality issue of foam degradation.

Lawsuits Have Been Filed Accusing Phillips Of Negligence And More

Numerous lawsuits have been filed over the foam degradation issues suffered by Phillips’ CPAP, BiPAP and ventilator devices. A federal judicial panel consolidated pretrial proceedings for over 110 federal lawsuits into a multidistrict litigation in October.

The lawsuits seek to recover damages based on numerous causes of action, including:

Negligence

Negligence is the failure to be reasonably careful to prevent harm from occurring. The lawsuits accuse Phillips of negligently designing and manufacturing dangerous devices, and negligently failing to warn users of the health risks that the devices pose.

Design Defect And/Or Manufacturing Defect

The lawsuits allege that Phillips’ devices can lead to users inhaling foam or dangerous offgassed chemicals because of a defective design and/or a defect in the process of making the devices.

Failure To Warn

The lawsuits allege that Phillips knew or should have known that their devices posed a health risk to users because of the foam degradation issues, yet failed to warn consumers about the health risk.

Nadrich Accident Injury Lawyers Is Representing Victims Of Phillips’ Dangerous CPAP, BiPAP And Ventilator Devices

Nadrich Accident Injury Lawyers is representing those who have been injured by Phillips’ recalled CPAP, BiPAP and ventilator devices. We have over 30 years of experience representing victims of dangerous products and offer no win, no fee representation.

Call us today at 800-718-4658 if you or a loved one was injured by a recalled Phillips CPAP, BiPAP or ventilator device. You may be entitled to financial compensation.